Summary of Research

Our research was carried out in conjunction with the Western Kentucky University team, and aims to evaluate the sustainability of dental tooth materials by quantifying the wear on new types of 3D printed and CNC machined dental tooth materials. The study was requested by an industry contact, Lee Coursey from Russellville Dental Laboratories, as there was no previous literature on these new materials. The goal of the project was to identify methods of effectively and decisively comparing the wear rates of the new dental tooth materials to industry standards, and to publish any significant results in a journal article.

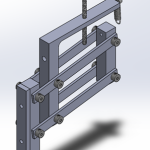

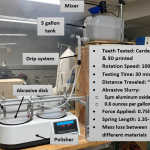

The team familiarized themselves with previous methods of quantifying dental wear, and proposed designs that would produce differentiable outcomes based on the literature. They selected a design that modeled a pin-on-disk type of setup, which was rendered in SolidWorks, a computer-aided design software. The team constructed mathematical models to ensure the structural soundness of the testing apparatus, and then detailed the design in a Bill of Materials.

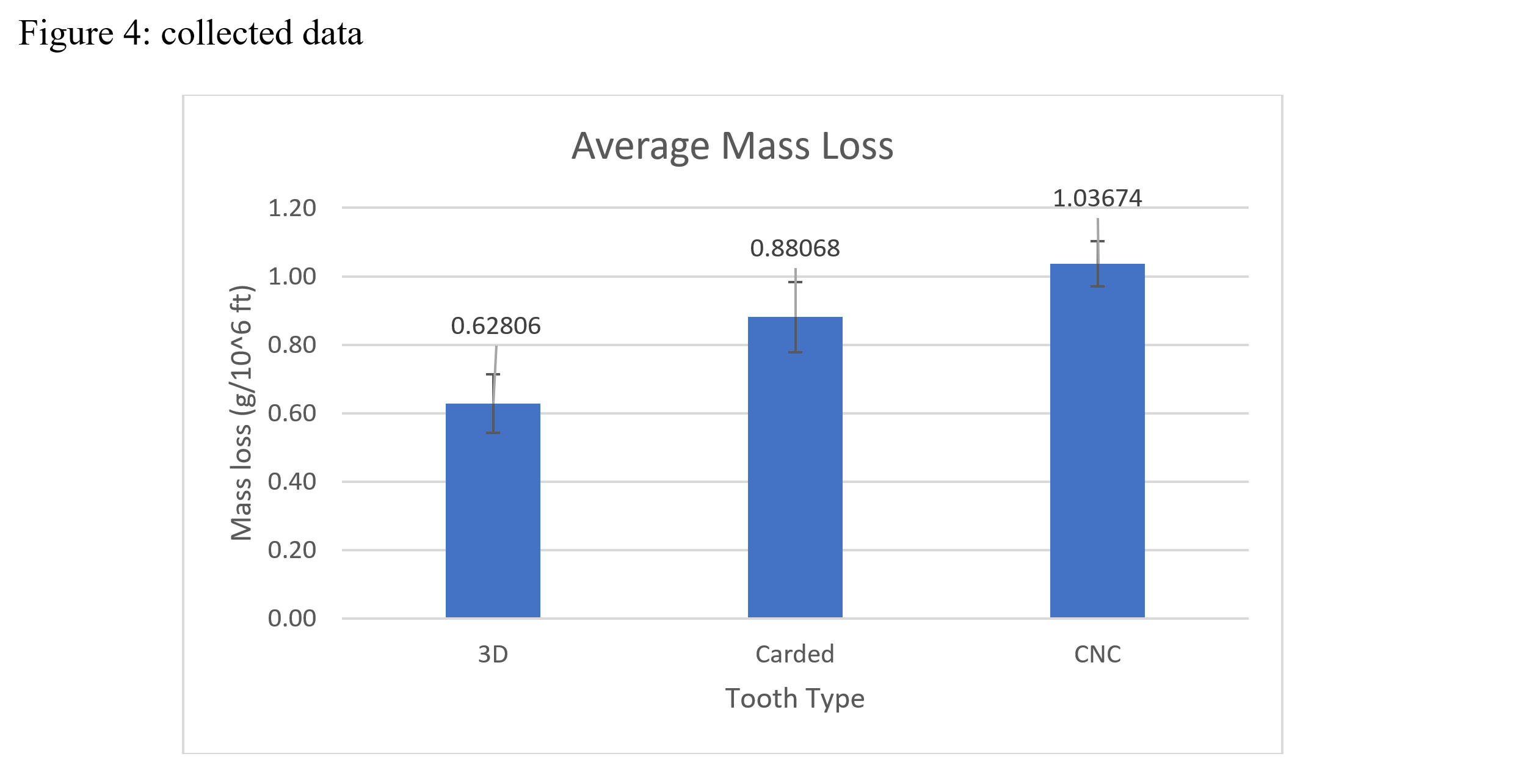

In the next semester, the team built and tested the machine using samples of 3D printed, CNC, and traditionally manufactured replacement samples. They recorded the mass loss to quantify wear in terms of mass lost per distance traveled. The study found that 3D printed replacements had an average wear of 0.62806±0.05868 g/10^6ft, CNC replacements had 1.0367±0.66574 g/10^6ft, and traditional manufacturing methods had 0.88068±0.10277 g/10^6ft.

The study indicates that 3D printing technology can produce dental tooth materials with wear rates comparable to traditional manufacturing methods. The study concludes that this could have a significant impact on the dental industry as it opens up new possibilities for producing dental restorations with improved wear resistance, at a lower cost and with a faster turnaround time. This study is significant as it adds to the knowledge in the field, and could pave the way for further research and development in this area.

Request a Copy of the Research

If you’d like to take a look at our unpublished research, we’d love to share with you. Fill out the form below and we’ll get in touch.

Quick Contact

Science References

- Methods CE. Clinical Evaluation and Laboratory Wear- Testing Methods. 2013. doi:10.1007/978-1-4614-4550-0

- Morozova Y, Holik P, Ctvrtlik R, et al. Methods of Wear Measuring in Dentistry. 2016;15(6):63-68. doi:10.9790/0853-1506116368

- Nimri GEM. Wear mechanisms and wear investigations of dental materials ; a review of the literature. 2015.

- Shafter M, Wicks R, Jain V, Nathanson D. Comparative In-Vitro Wear Resistance and Surface Roughnes of Chairside CAD/CAM Materials. J Dent Oral Disord. 2017;3(3):1-6.

- Mello PC, Coppede AR, Macedo AP, de Mattos M da GC, Rodrigues RCS, Ribeiro RF. Abrasion Wear Resistance of Different Artificial Teeth Opposed to Metal and Composite Antagonists. J Appl Oral Sci. 2009;17(5):451-456.

- Ruben JL, Roeters FJM, Montagner AF, Huysmans MCDNJM. A multifunctional device to simulate oral ageing : the “ Rub & Roll .” 2014;30:75-82. doi:10.1016/j.jmbbm.2013.10.019

- Reis KR, Bonfante G, Pegoraro LF, Conti PCR, de Oliveira PCG, Kaizer OB. In Vitro Wear Resistance of Three Types of Polymethyl Methacrylate Denture Teeth. J Appl Oral Sci. 2008;16(3):176-180.

- Shimane T, Endo K, Zheng JH, Yanagi T, Ohno H. Wear of opposing teeth by posterior composite resins -Evaluation of newly developed wear test methods-. Dent Mater J. 2010;29(6):713-720.